If a property has high or fluctuating demands for heating and hot water, multiple ground source heat pumps can be linked together in a cascaded system to efficiently meet the heat load.

If a property has high or fluctuating demands for heating and hot water, multiple ground source heat pumps can be linked together in a cascaded system to efficiently meet the heat load.

A cascaded ground source heat pump system allows heat pump units to work together to adjust to meet a property’s peak heat demand. It can be used to meet a high heat load, adjust to seasonal variations, maximise efficiencies of multiple temperature zones, add redundancy, and reduce overheating. When the demand for heat is low in the summertime, a unit in the system can operate in isolation to optimise efficiency and reduce running costs.

Refrigeration engineers might understand a cascaded ground source heat pump to mean a unit containing multi-stage compressors designed to take low-grade heat energy and convert this to a much higher temperature. A cascaded ground source heat pump system, however, can be defined in various ways.

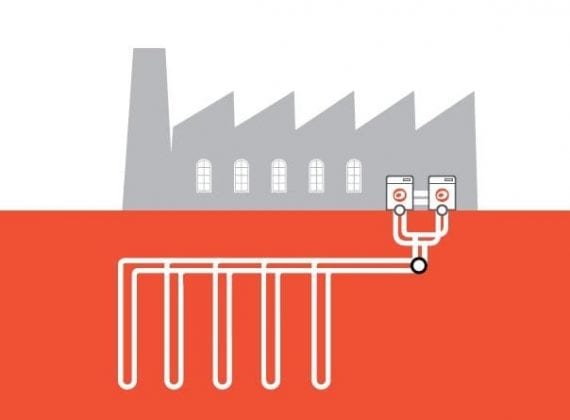

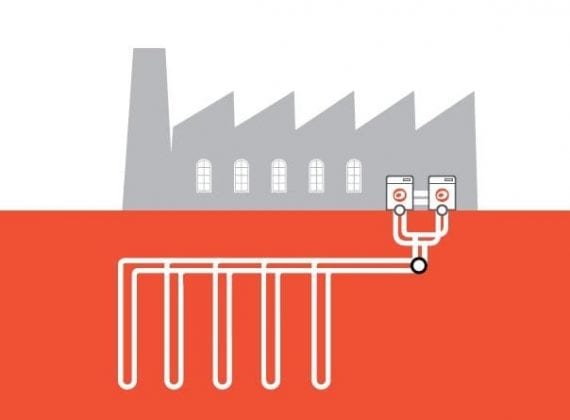

Cascaded ground source heat pump systems feature a central ground array infrastructure, typically made up of either slinkies or boreholes. This infrastructure is sized to deal with a building’s entire peak and annual heat demand. Typically a cascaded system will see the ground arrays connected to numerous large ground source heat pumps. These are then linked together in one central plant room.

Most commercial heating and plumbing contractors will be familiar with cascaded boiler systems. They are generally used in projects with large heat loads, or critical applications where a degree of redundancy is required within the heating system.

With a cascaded boiler system, the usual approach is to set up the boilers to operate at the temperature needed by the circuit requiring the highest temperature. Mixing or blending valves are then used to reduce the temperature down to what is needed by other circuits. Boilers are often set up to run at temperatures well above the maximum required.

In order to enjoy the many benefits of ground source heat pumps and efficiently deliver the heating and hot water demands of commercial projects, Kensa’s cascaded system is a much more elegant and efficient solution. If the same approach was taken with ground source heat pumps as boilers, the system would function, but it would be inefficient and result in significantly higher running costs for the client. Kensa would not recommend this approach.

Cascaded heat pump systems are particularly useful in commercial applications. Not only do they efficiently meet fluctuating heat demands, but each unit can have its own use. For example, one could be dedicated to providing heating while another is providing hot water. This avoids any delay in demand, making the set-up ideal for businesses.

Discover heat pump solutions

Cascaded ground source heat pump systems are designed to adjust between minimum and maximum heat demand as needed. This means that the system is highly efficient, as it only produces the necessary amount of heat and hot water.

In winter, a business might need 100kW of heat to satisfy demand. However, during the spring and summer, the need for heat is more likely to decrease to about 40kW. In order to avoid inefficiencies, the business installs a cascaded system with two 50kW units. When a load greater than 50kW is needed, both heat pumps will operate to fulfil demand – while only one will be used in the summer.

Cascaded systems can be designed to satisfy space heating and domestic hot water demands at the same time. These types of systems feature multiple ground source heat pumps with one or more dedicated to the production of hot water only and the remaining units dedicated to the space heating load.

The advantage of splitting the roles of the heat pumps is specialist high temperature ground source heat pumps can be used to produce the domestic hot water. This removes any reliance on immersion heaters. These types of cascaded systems may consist of three, four or even more heat pumps, where the domestic hot water and space heating loads are split again.

Cascaded ground source heat pump systems can adjust between minimum and maximum heat demands. This means that the system takes seasonal demand differences into account and economically produces heating without waste.

In the unlikely event that one unit breaks down, the system will continue to operate. Although the full heat load cannot be met, a degree of heat will be maintained in the building until the faulty unit is repaired or replaced or repaired. Engineers can then work on an individual heat pump while the rest of the system remains operational.

As ground source heat pumps operate at low flow temperatures, this not only improves overall efficiencies but reduces overheating. Overheating is a common problem in risers and corridors in the summer. This is most noticeable in older systems, where the pipe insulation is not up to modern standards and improving it is a logistical challenge.

Ground source technology gives the best efficiency when operated with long-run cycles. Modulating ground source heat pumps, either by frequent stop-start or the use of inverters, invariably causes efficiency loss. Having a cascade of ground source heat pumps means units can run almost continuously – for example, one can be dedicated to delivering hot water while another delivers the heating.

Kensa Sales Manager, Paul Dennison, further explains the advantages of cascaded systems:

Any high heating load can be matched with a cascaded system, as the central ground array, whether it is slinky pipe, boreholes or pond mats, is sized to deal with the property’s peak heat demand.

“This solution is becoming increasingly popular in commercial applications, such as in golf clubs, care homes and garden centres, where multiple heat pumps housed in a central plant room can satisfy demand for large volumes of heat and hot water.

The efficiency of ground source heat pumps is closely linked to their output temperature, as they are ideally low flow temperature systems. The lower the flow temperature of the radiators or underfloor heating system, the higher the efficiency of the heat pump – and the lower the running costs will be.

The efficiency of a traditional boiler (the conversion ratio between fuel and heat), is not greatly affected by the output temperature. Running the boiler at 40°C compared to an output of 60°C will only change the efficiency by a few percent. However, with a ground source heat pump, the efficiency difference at the same temperatures could result in a drop from 3.75 CoP to 2.25 CoP.

To accurately model the maximum required temperature of a heat pump, sensible measures can be taken to reduce it. For example, a building could increase the size of the heat emitters – such as radiators – or increase insulation levels.

Many commercial buildings have multiple temperature requirements across different heating distribution systems.

An office building requires Kensa’s heat pumps to produce three different temperatures: 35°C for the underfloor heating in the new extension, 65°C for the domestic hot water system, and 50°C for the old radiator system.

In this building, the radiator load is small, accounting for around 30% of the total heat requirement. It made no sense to run all the heating at 50°C and ignore the higher efficiencies possible on the underfloor heating circuit. In this case, each unit could share the same ground array, but separate ground source heat pumps could be installed and optimised for each circuit.

The key difference between this example and a typical cascaded ground source heat pump installation is that on the load side, the heat pumps won’t all be feeding into a common distribution system. Instead, the heat pumps are feeding two or three dedicated circuits with differing temperature requirements. If there is a greater demand for heat in the future, multiple heat pumps can be cascaded for heat on one or more circuits, effectively forming a series of cascaded systems in one system.

At Hornsea Garden Centre near Hull, the owners were looking to heat a new extension and upgrade the main building with underfloor heating. Kensa specified a cascaded ground source heat pump system featuring two 45kW Plantroom units to cover the heating, and one 25kW High Temperature Plantroom unit to provide hot water.

Charles, the owner of Hornsea Garden Centre, commented:

See the Hornsea case studyAs well as being energy-efficient, the technology makes perfect business sense compared to radiators or air source which work out more expensive.

Get in touch with Kensa to see if a cascaded system could suit your project.

Submit your project plans