No bluff! What’s the role of the buffer tank and when do you need one?

Heat pump installations, both ground and air source, will often but not always include a buffer tank. Guy Cashmore, Technical Director at Kensa Heat Pumps explains the role of the buffer tank, and provides recommendations for when they should or shouldn’t be fitted.

What is a buffer tank?

A buffer tank is typically just an insulated vessel of water; it doesn’t usually contain any coils or heat exchangers. Most will have top and bottom connections and some will have a baffle plate internally. Buffer tanks shouldn’t be confused with thermal stores as they are not a substitute for a hot water cylinder.

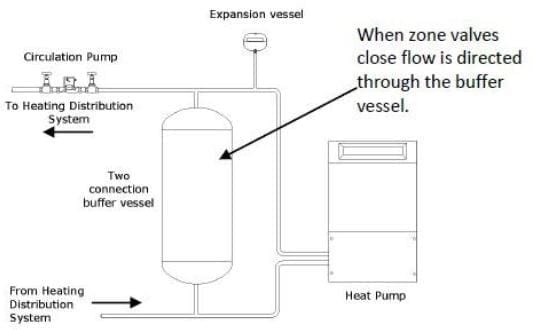

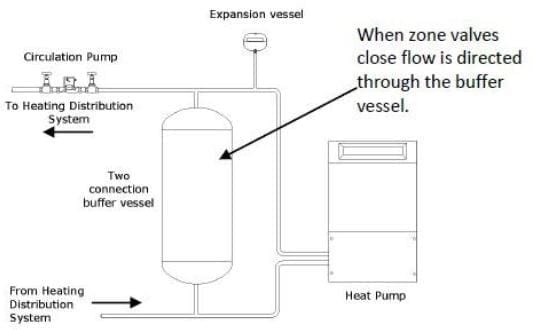

The primary role of a buffer tank is usually to keep a minimum volume of water ‘in circuit’ at times when the heating load is very low. This prevents the heat pump from short cycling and provides a bypass route to maintain the minimum flow rate through the heat pump if most of the heating zones have shut down. Both the minimum flow rate and the minimum volume of water in circuit are necessary to keep the heat pump happy.

Short cycling can causes a number of issues: loss of energy efficiency, reduced compressor life, power network disruption and, very rarely, sudden compressor failure due to lubrication starvation. So it really is best avoided!

Not all systems have or need a buffer tank. Quite often it is possible to use the heating distribution system itself as the buffer, assuming that a number of zones or radiators can be left permanently open and uncontrolled, then the minimum flow and volume requirements can be met by the system itself. A good rule of thumb is ten litres of water per kW of heat pump capacity for the volume and two litres per minute per kW for the flow, but obviously different manufacturers will have varying requirements in this respect and this needs to be carefully followed.

What’s the best way to connect one?

If a buffer tank is to be used, then the way it is connected is important. Traditionally they have tended to be connected ‘four pipe’ – flow in and out to the heat pump and flow in and out to the heating system. The down side of this arrangement is that the buffer becomes a permanent mixing point on the system, causing a permanent temperature step in the system. Although one or two specific exceptions do exist, this design should be avoided if possible as it will cause a permanent drop in system efficiency for no gain whatsoever.

A better arrangement (and the Kensa recommended way), is to connect a buffer tank using two connections only. This will prevent most of the flow passing through the buffer under most operating conditions, so minimising mixing, only under very light heating load will most of the flow enter the buffer – so the buffer only comes into play when actually necessary.

The buffer can be a good place to inject extra heat from other sources. By adding a coil within the buffer it can be used with excess solar heat, or heat from a backup boiler. By adding an electric immersion heater in the buffer, surplus PV power can be converted into useful heat using a PV controller. If using it with a backup boiler, then it is probably a good idea to connect the buffer ‘four pipe’ to get maximum heat transfer.

What about thermal stores?

The unwary could easily think that fitting a thermal store was a good substitute for both a buffer tank and a hot water cylinder, but when sourced from a heat pump this is not a good idea. Although the thermal store will usually function OK as a buffer, they don’t make good partners for heat pumps as all the space heating load then has to be served at DHW production temperatures – this will typically lead to very poor efficiency and result in high electricity bills.

A buffer tank can also be used for daily energy storage, although currently in the UK due to the lack of viable variable rate electricity tariffs these types of installations are rare. To serve this purpose the buffer will often have to be several thousand litres – finding a suitable location for this in a property without a basement can be a challenge. It also needs to be very well insulated to avoid the heat losses negating any running cost saving. The heat pump runs when the electricity is cheap, heating up the buffer. Later on, when electricity is expensive but heat is required, the energy stored in the buffer can be delivered to the house with only a low wattage circulator pump required to run. Systems like this don’t actually save any energy, indeed they may actually increase energy consumption slightly due to the system losses, but they can, given the right tariff and good design, reduce the running costs significantly.