The process of making boreholes for ground source heat pumps

1. Drilling a ground source heat pump borehole

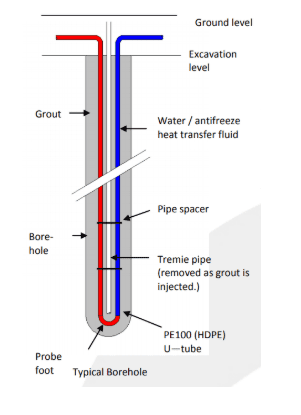

A borehole consists of a hole drilled between 60 to 200m deep. Typically, the diameter of a borehole is around 110 to 150mm, but this depends on the type of machine being used to drill the borehole. It also depends on the diameter of the borehole pipe, which is usually between 32 to 40mm.

The first few metres of a borehole is generally sleeved with a casing to prevent the sides from collapsing. The depth of this casing depends on the material that the borehole is drilled into and the depth of soil.

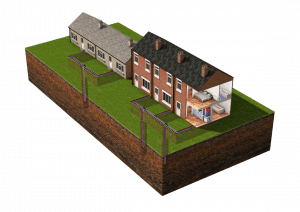

Multiple boreholes are generally placed 5 to 6m apart. However, for large commercial projects, the interference from one borehole to another must be calculated to ensure there is adequate spacing and sufficient depth between them.

The drilling rigs used for boreholes come in many shapes and sizes. Small drilling rigs can operate in restricted access sites and small gardens, while others are designed for larger commercial projects.

2. Inserting the borehole pipework for the heat pump

A single loop of pipe – usually PE100 HDPE or Pex pipe – is inserted into the borehole. Along with the borehole pipe, a small tremie pipe, which is about 25 to 40mm, is also attached to the borehole pipe.

The tremie pipe is used to fill the borehole with thermal grout and is withdrawn as the grout is injected. The grout provides a thermal path, which allows the energy within the ground to be absorbed by the fluid circulating the borehole pipe. The driller will take responsibility for grouting the hole using specialist pumping equipment.

Single loops are normally used in the UK, but it’s possible to use a twin loop or duplex system to try and extract more energy.

A larger diameter hole is required for a twin loop system, and the borehole’s energy yield only increases by an approximate factor of 1.25. This also depends on the hole and pipe diameter, the distance from the next borehole, how the pipe is inserted, and the thermal grouting. The pipe is either filled with water or weighted at the end, making it easier to insert into the borehole.

3. Testing the ground source heat pump borehole

The drilling contractor will perform a pressure test, cap the plastic ground array pipe, and issue a certificate before leaving the site.

For larger commercial projects (nominally over 100kW), guidelines tend to overestimate the number of required boreholes. It’s recommended that a thermal response test (TRT) is carried out on a representative borehole. A thermal geologist can then combine the results from a TRT, with the heating and cooling profile of the building, to calculate the type, depth, number and spacing of boreholes. The cost of completing a TRT is generally recovered in the reduction in the number of boreholes required.

4. Connecting the boreholes to the ground source heat pumps

If more than one borehole is required, the pipes should be connected using a manifold. This ensures equal distribution of flow across each borehole. Manifolds can be located at the building or the pipes can be connected in a subterranean manifold within a trench at the edge of the bore field.

To avoid any joints and eliminate the need for any electrofusion welding – which requires specialist equipment and can attract additional costs – it’s sensible to use specially extended borehole probes. These are simply laid in a trench between the top of the borehole and the manifold on the side of the building.

Kensa recommends you compare the rates of groundwork contractors and drilling contractors to identify the best price for this trenching work.

Is a ground source heat pump borehole right for my project?

Choosing the right ground array is an important stage of any ground source project. Kensa can help you with anything from specification and sizing to design and aftersales support.

Submit your plans for advice