Our Technical Director Guy Cashmore has put together some helpful hints about ensuring you get the design and installation of the ground array right.

Our Technical Director Guy Cashmore is a regular columnist for Heat Pumps Today magazine and writes on a monthly basis about hot topics within the heat pump industry.

He has put together some helpful hints about ensuring you get the design and installation of the ground array right.

You can view the article on page 10 of the online issue here. Alternatively, you can read the article in full below:

Going to ground: The unbendable rules of ground arrays*

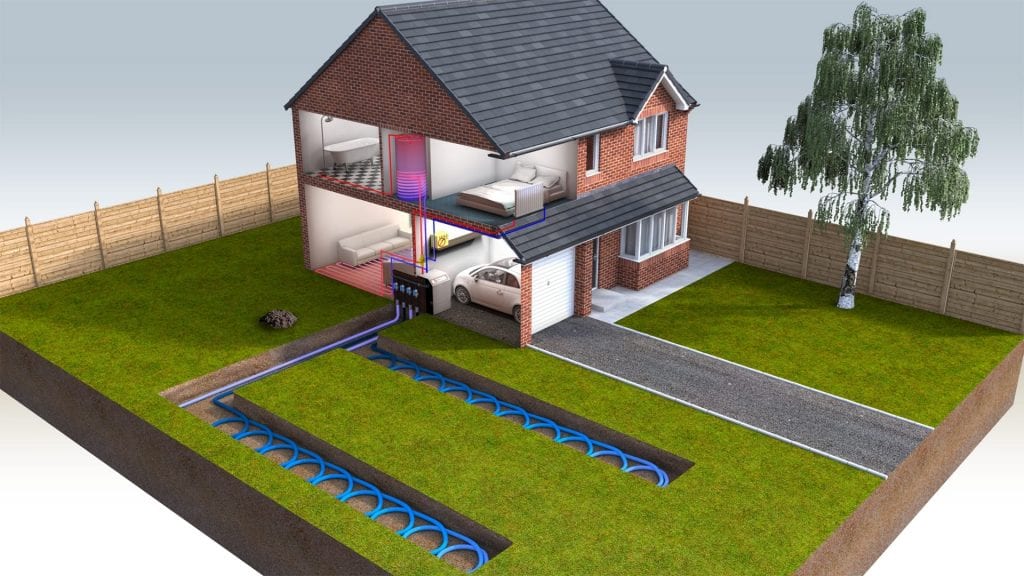

The ground arrays for a ground source heat pump installation are typically the most expensive element to install but also the least well understood. Usually in the UK a ground array for a ground source heat pump will be either a horizontal array using straight pipe or loops (aka slinkies) in trenches, or a vertical array using U tubes that are inserted into boreholes. Getting the design and installation of the ground array right is absolutely critical to the end result; the ground array is the energy supply to heat the building. You can have the latest all singing and dancing ground source heat pump, but if the ground array doesn’t deliver, you won’t be getting any heat.

The source needs to be equal to or greater than the heat load

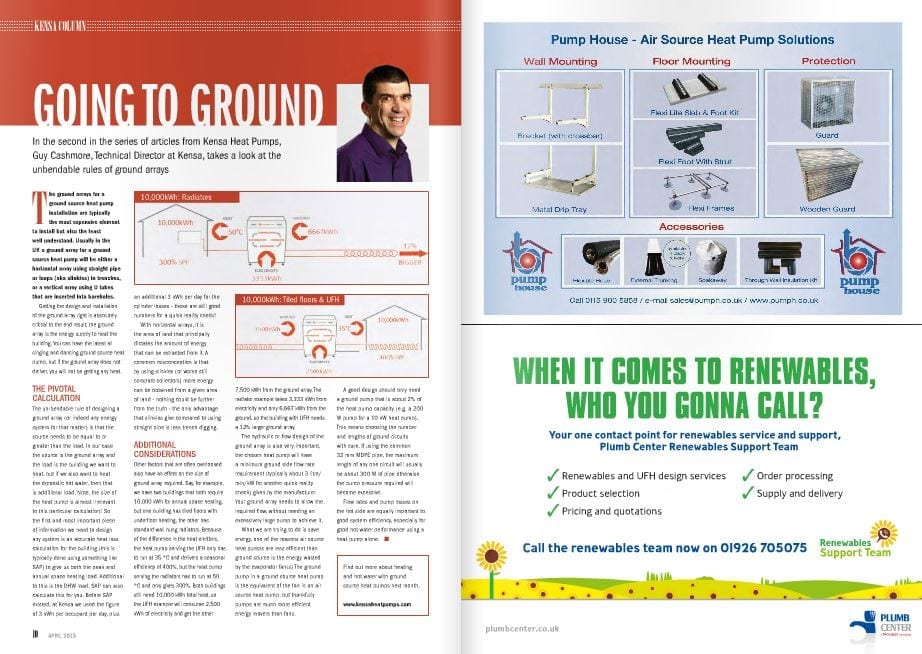

The un-bendable rule of designing a ground array (or indeed any energy system for that matter) is that the source needs to be equal to or greater than the load. In our case the source is the ground array and the load is the building we want to heat, but if we also want to heat the domestic hot water, then that is additional load. Note, the size of the heat pump is almost irrelevant to this particular calculation! So the first and most important piece of information we need to design any system is an accurate heat loss calculation for the building (this is typically done using something like SAP) to give us both the peak and annual space heating load. Additional to this is the DHW load, SAP can also calculate this for you. Before SAP existed, at Kensa we used the figure of 3 kWh per occupant per day, plus an additional 3 kWh per day for the cylinder losses – these are still good numbers for a quick reality check!

The area of land dictates how much energy can be extracted

With horizontal arrays, it is the area of land that principally dictates the amount of energy that can be extracted from it. A common misconception is that by using slinkies (or worse still compact collectors) more energy can be obtained from a given area of land – nothing could be further from the truth – the only advantage that slinkies give compared to using straight pipe is less trench digging.

Other factors to consider

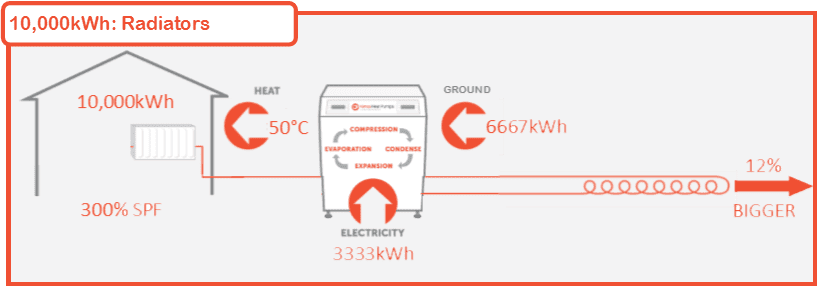

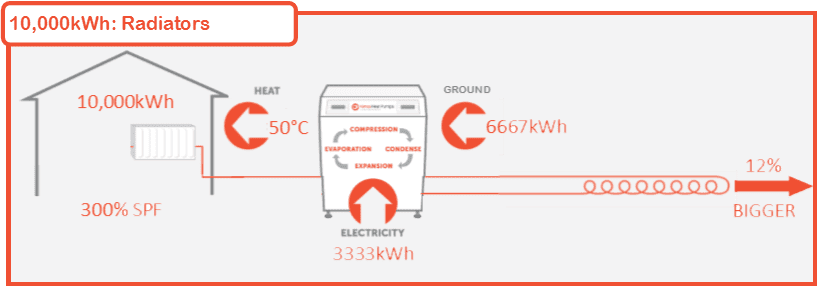

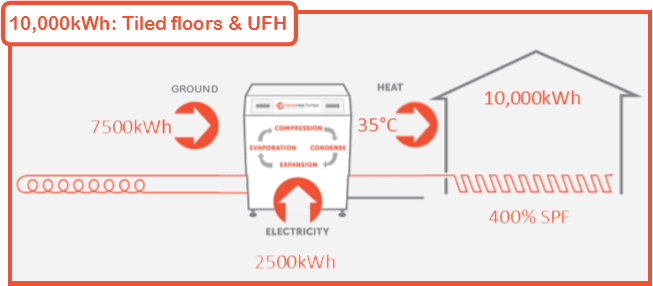

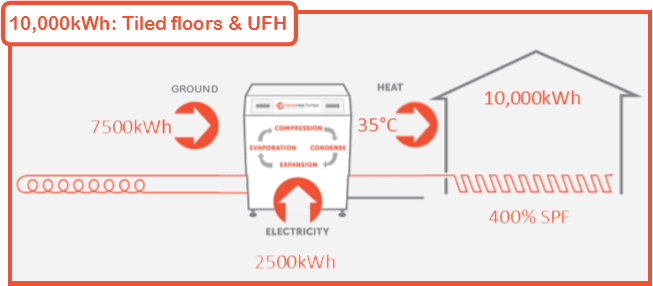

Other factors that are often overlooked also have an effect on the size of ground array required. Say for example we have two buildings that both require 10,000 kWh for annualspace heating, but one building has tiled floors with underfloor heating, the other has standard wall hung radiators. Because of the difference in the heat emitters, the heat pump serving the UFH only has to run at 35 °C and delivers a seasonal efficiency of 400%, but the heat pump serving the radiators has to run at 50 °C and only gives 300%. Both buildings still need 10,000 kWh total heat, so the UFH example will consume 2,500 kWh of electricity and get the other 7,500 kWh from the ground array. The radiator example takes 3,333 kWh from electricity and only 6,667 kWh from the ground, so the building with UFH needs a 12% larger ground array..

The hydraulic or flow design of the ground array is also very important, the chosen heat pump will have a minimum ground side flow rate requirement (typically about 3 litre/min/kW for another quick reality check) given by the manufacturer. Your ground array needs to allow the required flow, without needing an excessively large pump to achieve it.

What we are trying to do is save energy, one of the reasons air source heat pumps are less efficient than ground source is the energy wasted by the evaporator fan(s) The ground pump in a ground source heat pump is the equivalent of the fan in an air source heat pump, but thankfully pumps are much more efficient energy movers than fans.

A good design should only need a ground pump that is about 2% of the heat pump capacity (e.g. a 200 W pump for a 10 kW heat pump). This means choosing the number and lengths of ground circuits with care. If using the common 32 mm MDPE pipe, the maximum length of any one circuit will usually be about 300 M of pipe otherwise the pump pressure required will become excessive.

Flow rates and pump losses on the hot side are equally important to good system efficiency, especially for good hot water performance using a heat pump alone.

Find out more about heating and hot water with ground source heat pumps next month.

*Published online in Heat Pumps Today magazine April 2015