Get to grips with ground source

This blog post offers top tips for self-builders and renovators considering integrating a ground source heat pump into a building to help ensure optimum efficiencies, resulting in lower emissions, lower running costs and high financial returns through the Domestic Renewable Heat Incentive (RHI: this scheme has now closed – please visit this page to explore other funding).

1. Peak Load

Ground source heat pumps should be sized in accordance with the peak heating load of the building.

Heat pumps are low-flow temperature devices; the lower the flow temperature for the heat distribution system, the less work for the heat pump – enhancing the system’s efficiency.

Therefore, it is important that the building is insulated as much as possible. If the building is not insulated sufficiently then the heat pump will have higher running costs – and you may require a bigger (more expensive) heat pump to deliver the heat required.

For a ground source heat pump, the ground arrays should be sized to the peak heating load and hot water demand of the building. There are different types of ground arrays available depending on the heat sources available to you, be this soil (slinkies), rock (boreholes), or water sources such as lakes, rivers, and even the sea (pond mats).

The most common ground array is slinkies; slinkies typically require twice the area of the footprint of your property. If space is limited, boreholes are a good option, reaching depths of between 80m – 150m. Water sources are more efficient and require minimal digging so are less costly – if a water source is available to you, then this would be your recommended heat source for a ground source heat pump.

Watch the video below to see how one ground source heat pump project was achievable in a Grade II listed property thanks to energy efficiency measures and a pond mat.

2. Heat Emitters

To get the most efficient operation from a heat pump, it is important that the outlet temperature for your heating distribution system is kept as low as possible – this lends itself well to underfloor heating.

Underfloor Heating (UFH)

Underfloor heating embedded within screed will generally require the lowest flow temperature. Using the screed as a thermal mass allows the occupier to run the heat pump on off-peak tariffs, further reducing the running costs. If you are using underfloor heating, the underfloor company should design the layout of pipe for the construction and work out the thermal resistance of the floor covering to establish the optimum running temperature. Your heat pump manufacturer will then set the heat pump to the UFH design temperature during commissioning.

Remember floor coverings like carpets need to be factored into your sizing. This coupled with, normally, a lower tog carpet on top means the heat pump will require setting at a higher temperature.

Radiators

To get the most efficient operation from a heat pump, it is important that the outlet temperature is kept as low as possible. For this reason, underfloor heating, with its larger heat-emitting area, has generally been favoured.

However, where this is not possible, radiator systems can be used but must be oversized to deliver flow temperatures compatible with the heat pump (typically 45ºC). If using radiators with your ground source heat pump, be sure to take into account:

-

45-50ºC flow temperature

Heat pumps with radiators are required to increase their flow temperatures to 45-50ºC, which reduces the Coefficient of Performance (COP) and hence efficiency.

-

Oversized hot water coils are required

The larger the size of the coil within the tank, the better the heat transfer area and hence the better the DHW performance will be. Due to the low flow temperatures generated by the heat pump, the hot water tank must have an oversized coil to provide the correct heat transfer.

-

Off-peak tariffs

Due to the low water content of radiator systems and hence low thermal storage, off-peak tariffs such as Economy 10 cannot be effectively used and a flat rate tariff might be more effective.

The manufacturer of the radiators you choose will have correction tables to work out the output of the radiators based on the lower flow temperature required and the room heat loss.

For advice on the impact of floor coverings and heat distribution systems, read the official Heat Emitter Guide here.

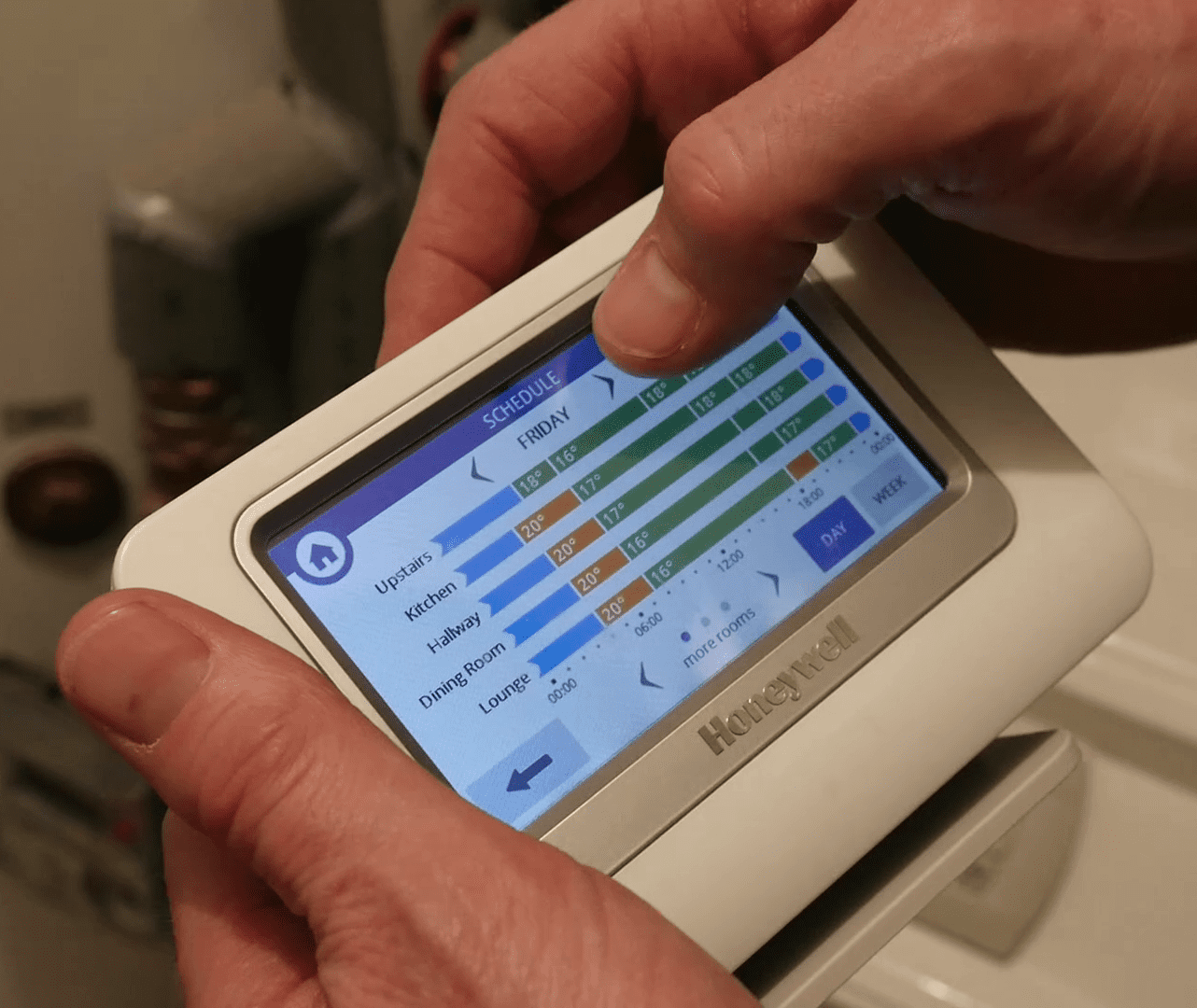

Controls

Due to the low flow temperature of ground source heat pumps and their heat emitters, efficient use via heating controls is essential to ensure maximum savings. Your choice of controls is dependent on the degree of sophistication you require from your system, from simple dial controls to fully programmable stats.

3. Hot water

Ground source heat pumps can provide hot water production to a comfortable 55ºC. Where there is an exceptional hot water demand, high-temperature models are available to deliver hot water to 65ºC. The higher the hot water production, the lower the heat pump efficiency.

When searching for a hot water cylinder compatible with your ground source heat pump, look out for stainless steel pressurised cylinders with large internal coils to compliment the heat pumps performance.

The cylinder, if possible, should be located in a central location inside the house, this keeps the domestic hot water pipework to a minimum. Any pipework from the cylinder to the point of use should be well insulated to avoid any drop in temperature between the cylinder and taps.

4. Location

Depending on the building and external environment, the ground source heat pump may be required to work long hours. This isn’t a problem for the heat pump as it is a very robust piece of kit.

Custom-built shelters, outhouses, and garages are the favoured option by many, however, some manufacturers also offer smaller and quieter models that can be installed inside the home (for example, the Kensa Shoebox in smaller spaces or the Evo, which has a modern, sophisticated design).

Find out more

Unearth the benefits of ground source heat pumps for self-builders here.