In this article, the Technical Support Team at Kensa Heat Pumps gives their top tips for proactive maintenance on ground source heat pump systems to ensure your customers stay warm and cosy throughout winter.

Before we go into details about heat pump maintenance, if your customers are worried about the price of energy bills, please do share with them this article with Kensa’s heat pump energy saving tips. With the cost of living on the rise and cold weather hitting, people will be thinking about how to keep their energy bills as low as possible. We offer advice on how consumers can lower their energy usage, making their homes more efficient to help to reduce the cost of their energy bills.

One of the unique benefits of ground source heat pumps is their minimal maintenance requirements and long life expectancy. However, as with all heating systems, it is good practice for the heating distribution system, including energy collectors, to be proactively checked and maintained to ensure optimum performance when colder weather is on the horizon.

Temperatures below ground remain relatively constant all year round, so a sudden drop in air temperature during winter will not affect the performance of a ground source heat pump, nor does the impact of exposure to the elements affect the operation, as it would an air source heat pump.

Heating Distribution System

Tom Worth, Kensa Technical Support Manager, says:

Well designed ground source heat pumps require only a minimal amount of maintenance, however, it is important that the whole system is checked.

Tom recommends the following basic checks are made on the heating distribution system:

- Check the inhibitor levels and ensure no corrosion or degradation has occurred.

- Encourage your customer to regularly clean the convector fins of their radiators with a long-handled radiator brush or the nozzle attachment of a hoover.

- Make sure that all pump valves and actuators on the system are functioning correctly.

- Ensure all room stats and programmers are operating correctly and are programmed correctly.

- If any components require a battery to function, check that the battery has charge.

- If the system has filters or a MagnaClean, check that this is cleaned and/or serviced.

- Check the pressure of the ground and heating system; Kensa recommends that it is above 2 bar.

- Perform a gas charge pressure check on the expansion vessel.

- Check antifreeze concentration and health.

Renewable Energy Collectors

Tom Worth, Kensa Technical Support Manager, says:

This is where the maintenance of a ground source heat pump system becomes slightly different to that of a standard fossil fuel system, as it is important to ensure that no issues can occur in the collectors that harness the renewable energy from a ground or water source.

Any issues with the energy collection system could mean the heat pump has to work harder and hence becomes less efficient. In the worst case, the source energy could become depleted causing the heat pump to stop operating altogether.

Tom recommends the following quick and easy checks on ground source heat pump energy collectors:

Slinky pipe and sealed boreholes

- Samples of thermal transfer fluid should be taken and the concentration of the antifreeze solution measured using a refractometer.

- After a number of years, the concentration of antifreeze solution within the ground arrays can drop due to possible top-ups of fresh water to maintain the ground array pressure. Antifreeze solution provided by Kensa contains an anti-bacterial agent and an inhibitor to avoid bacterial growth and corrosion. Maintaining the correct concentration of this antifreeze solution is important as it will stop the system from freezing and also prolong the lifespan of the circulation pump. The bacterial agent will ensure no bacterial growth occurs, thus further increasing the lifespan of the antifreeze.

- The manifold should be thoroughly inspected, checking that any insulation is still in good condition and the components are still fit for purpose. Ground array manifolds on the ground collector can suffer from condensation due to the low temperatures of the thermal transfer fluid, which if not properly controlled can cause damage.

- After a period of time any disturbed ground will settle, so manifolds should be checked for strain on pipework connections caused by ground settlement. It can take up to 12 months for any disturbed ground to fully settle and if any pipework is under strain this must be remedied.

- The pressure of the thermal transfer fluid within the ground array should be checked and increased if required. Kensa recommends that it is above 2 bar.

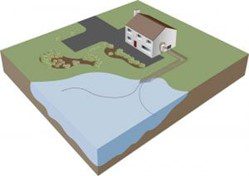

Pond Mats

- It is advised that pond mats are inspected, cleaned and maintained regularly. After a period of time sediment, mud and leaves could build up around and under the pond mat collectors causing a potential loss of performance and reduced ability to harvest heat from the water.

Open Loop

- Check the manufacturer’s guidelines on maintenance for external heat exchangers. Manufacturers of plate heat exchangers can recommend that the plate gaskets are replaced every two years.

- Any external filters or treatment systems fitted to an open loop system should also be checked

and maintained in line with the manufacturer’s guidelines.

- Open loop heat exchangers can suffer from condensation damage due to running with liquid at lower than ambient temperatures, which if not properly controlled can cause damage. Any heat exchanger should be inspected checking that any lagging is still in good condition and any components are still fit for purpose. If corrosion has started, these areas can be treated to preserve their longevity.

- The open loop pump and pump control may also need to be maintained and it is advisable to check with the manufacturer or suppliers for their recommendations.

- Particularly for any surface water sources, check inlets and outlets are free from vegetation and also from any flotsam and jetsam.

Contact Kensa’s Technical Support Team

Kensa Heat Pumps has a dedicated Technical Support team that can help, advise and direct any enquiries about Kensa Heat Pump systems. They can be contacted on 0845 680 4328.