In this blog, first published in Heating & Plumbing Monthly in September 2017, Guy Cashmore, Technical Director for Kensa Heat Pumps argues that the renewable industry needs to embrace the thousands of potential new installers who are currently working with boilers.

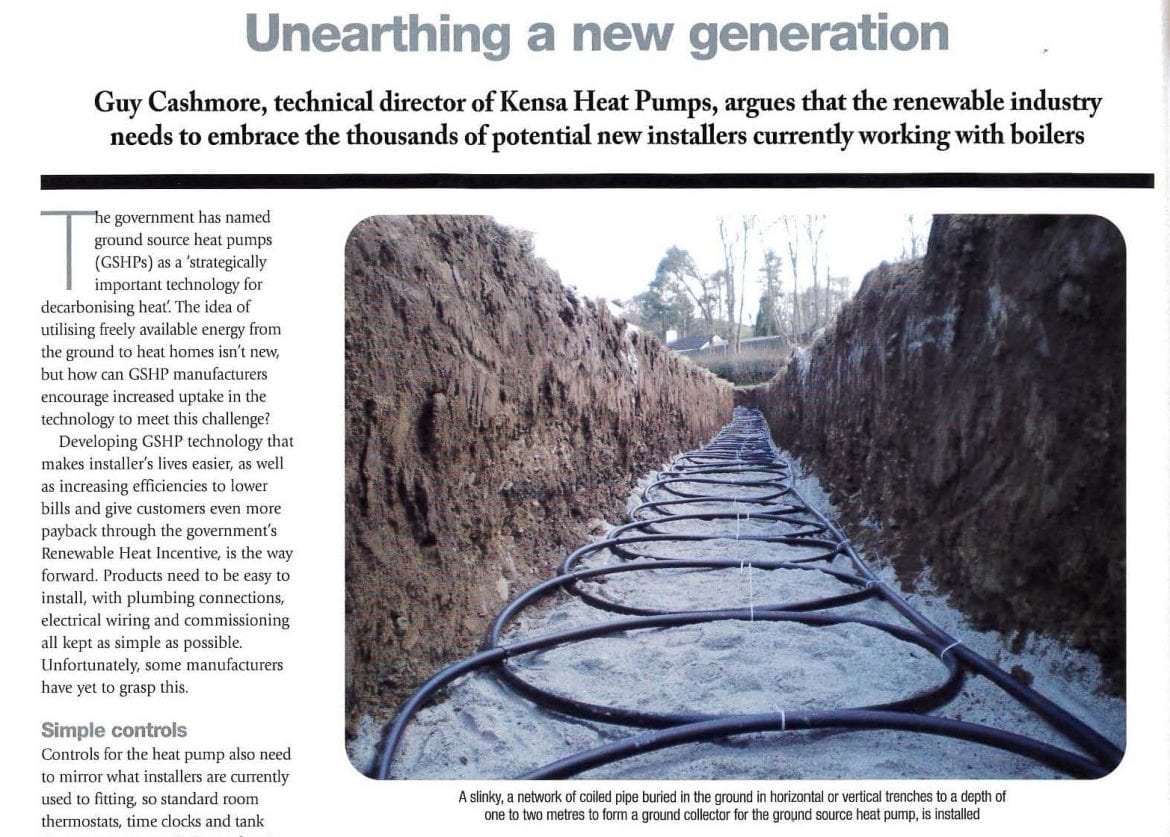

The Government has named ground source heat pumps as a ‘strategically important technology for decarbonising heat’. The idea of utilising freely available energy from the ground to heat homes isn’t new, but how can ground source manufacturers encourage increased uptake in the technology to meet this challenge?

Guy says:

Developing ground source heat pump technology that makes installers lives easier, as well as increasing efficiencies to lower bills and give customers even more payback through the Government’s funding (please visit this page) is the way forward. Products need to be easy to install, with plumbing connections, electrical wiring and commissioning all kept as simple as possible. Unfortunately some manufacturers have yet to grasp this.”

Simple controls

“Having simple controls also future proofs heat pumps for use with battery storage systems and phase change heat storage in the future – both of which are close to becoming mainstream but we don’t know the details of yet. This allows the heat pump to be run as a simple ‘on demand’ unit with control coming from elsewhere.

“Water pumps for both the ground and heating side should be factory built in, saving time during installation and ensuring the pumps are right for the job. Incorrect pump speed adjustment is a major cause of wasted energy, but if the pumps are included in the unit they can be speed controlled automatically from the heat pump’s own controls based on the flow and return temperatures. It’s a no brainer when you think about it.”

Achieving efficiency

“Getting the very best efficiency out of any heat pump system also requires careful setting up and usage, but how does anyone know if making a change has made things better or worse? Although many systems are now fitted with a heat meter, getting an accurate CoP (Coefficient of Performance) figure is still difficult.

“Kensa thinks that ground source heat pumps should be able to deliver a ‘live’ CoP readout. Car manufacturers have been fitting MPG gauges for years, so our industry has some catching up to do! This is why our new Evo Series features an industry first ‘live’ CoP readout that delivers data directly from the operating conditions in order to combat this uncertainty.

“Domestic hot water systems using heat pumps always require close attention if decent hot water is to be delivered. This is especially the case if expensive use of immersion heaters is to be minimised or avoided completely. Having the two items controlled separately is never going to deliver best results. Ideally the immersion won’t be needed at all, but when it is then obviously it should be switched on only after the heat pump has already raised the temperature as much as possible, not before or during heat pump operation. A simple immersion control switched output from the heat pump is all that’s needed.”

Guy also adds:

“Some manufacturers are offering ‘inverter driven’ heat pump models, which essentially are electrical controls to theoretically adjust the heating output automatically according to demand. However Kensa believes that inverters on ground source heat pumps deliver few advantages, in real world operation rather than test lab conditions they don’t improve efficiency. They do add cost, complexity and likely future reliability issues. Class leading efficiency should be delivered using robust and well-designed mechanical components with a 25 year design life, not test cheating electronics.”

For more information about the new Kensa Evo Series visit www.kensaheatpumps.com/evo