Futurebuild 2023

Updated: 24/03/2023

The pioneering project, Heat the Streets, is run by Kensa Utilities and part funded by the European Regional Development Fund (ERDF), and represents a significant investment in the future of sustainable energy.

Each home involved in Heat the Streets will swap either carbon intensive oil or LPG fossil fuels for its own low carbon Kensa ground source heat pump that will provide 100% of the property’s heating and hot water year round. Homeowners will pay a monthly standing charge to access the heat network, much like the existing gas connection fee.

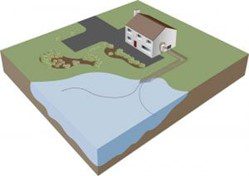

The in-road ground source heat pump network, also known as Networked Heat Pumps, in Collins Parc, Stithians, will consist of 42 boreholes, drilled to an average depth of 106m. It allows homeowners to utilise the heat from the ground to keep their houses warm and reduce carbon emissions. The infrastructure emulates the existing gas grid and has been designed to accommodate future connections, allowing households who were not ready to change their heating system to connect at a later date.

Unlike traditional district heating, there is no need for a central plant, no heat loss around the network, and customers can still change their energy provider at will, promoting energy independence.

Heating accounts for around 30% of the UK’s carbon emissions and The Committee on Climate Change estimates 80% of the buildings that will be here in 2050 have already been built. As ground source heat pumps are electrically powered, non-combustion devices that emit no local emissions or air pollution, they will reduce the carbon output associated with heating each home by around 70%.

Wouter Thijssen, Managing Director of Kensa Utilities comments:

It’s fantastic to have the first heat pump up and running on this landmark project which provides a blueprint for the decarbonisation of heating in the UK. Our model replicates the gas network with a pipe in the ground, a flat rate standing charge to consumers and a little white box in the house.

Just as Burton Upon Trent was the first UK town to convert to natural gas in 1968 – at the time a cheaper, better, cleaner fuel than towns gas – we believe Stithians is the first UK town to convert to the 21st-century equivalent: networked heat pumps. Residents will have access to a network that will provide cheaper and cleaner heat for 100 years to come.

Some locals have already been connected to a parallel scheme in Stithians which involves drilling a borehole into their front drive. They’re delighted with the results from their Kensa ground source heat pumps.

Caroline Bolitho, resident of Stithians who’s heat pump was switched on today comments:

As a grandma I feel that I’m doing my bit for future generations and reducing my carbon footprint by having a ground source heat pump system which is important. I have been using oil heating before this and i feel really privileged and excited to have the system up and running.

Jackie Barson, a resident of Stithians is already connected, she commented:

I am happy with it. It’s smart and efficient. It’ll take a few weeks to fully get to grips with the operation, but I have no regrets. I do know there are other residents who are disappointed they’re not part of the project.

Kensa believes that street-by-street deployment of this infrastructure is the most efficient way for the country to reduce the carbon output associated with heating for the lowest overall system cost.

In order to make projects like Heat The Streets easily replicable across the country, effective zoning and the granting of statutory rights for heat networks are crucial.

Summary:

Summary:Residents and their families at three council-owned tower blocks in Chadwell St Mary are benefiting from a newly improved community room and brand-new community pantry initiative, thanks to a collaborative partnership between Thurrock Council and Kensa Contracting.

On Tuesday 7 March, local residents from Gooderham House, Poole House and George Tilbury House joined Cllr Qaisar Abbas, Cabinet Member for Culture and Communities, to experience their new community room in George Tilbury House at a special event. Residents enjoyed refreshments, while children were invited to take part in arts and crafts activities.

Summary:

Summary:As part of an extensive energy-saving overhaul delivered by Kensa Contracting, Richmond Hill Primary Academy, part of the Roselearning Trust, in Doncaster, is having a low carbon ground source heat pump system installed, allowing the school to focus on teaching without having to worry about heating.

For many years, the large primary school lacked properly functioning central heating, with some children having lessons in temporary classrooms with interim gas heaters. These systems were costing the school lots to run, emitting lots of carbon dioxide, and were ultimately ‘stop-gap’ measures for the real problem of the redundant gas central heating system and poor insulation in the main building.

Summary:

Summary:Kensa Contracting and Thurrock Council celebrated an important milestone as the first energy and carbon saving ground source heat pump was switched on. It is one of over 270 residences benefiting from a landmark energy upgrade scheme delivered by Kensa Contracting.

Kensa’s sustainable, low carbon ground source heat pumps are replacing night storage heaters in three social housing high-rise tower blocks at Chadwell St Mary in Thurrock. They are estimated to reduce fuel bills by over 50% for some households, due to them being three times more energy efficient.

Summary:

Summary:Kensa Contracting win District Heating Project of the Year at the H&V News Awards 2022 with Daisyfield’s project and were Highly Commended for Heat Pump Project of the Year – Residential.

Residents living in three tower blocks in Blackburn are benefitting after receiving an award-winning renewable refurbishment. The people living in Daisyfield Towers in the Lancashire town have had their old, outdated and inefficient gas boilers replaced by ground source heat pumps.

The switch is expected to save 6,556 tonnes of carbon monoxide emissions over the next 20 years – the equivalent of taking 1,413 cars off the round for a whole year, or 283,781 bags of waste being recycled instead of landfilled.

133 new energy-efficient homes comprising of 2, 3 and 4-bedroom houses and 1 and 2-bed apartments have been built for Bristol City Council by Willmott Dixon. The housing development, Ashton Rise, in Ashton Vale, South Bristol is part of Bristol City Council’s commitment to build 2,000 new homes in the city including 800 affordable homes.

The 19-month project, worth £263K is part-funded by Department for Energy Security & Net Zero through their Net Zero Innovation Portfolio (NZIP). Kensa, the UK’s leading ground source heat pump specialist, is one of thirty-seven British companies to get a share of a £19 million Energy Entrepreneurs Fund: phase 9.

Kensa’s new project – PREDICT (Predictive Remote Engineering Diagnostics Integrated Communication Tool) – will develop a user-friendly dashboard that processes and interprets heat pump operating data, allowing end users, installers and landlords to remotely manage the health of their heat pumps.

Using AI, the dashboard will provide alerts of potential faults before they occur and suggest how to combat them through a predictive and proactive maintenance package. This pioneering feature will give PREDICT the capability to improve customer experiences and prolong heat pump unit lifespans.

Dan Roberts, Technical Director at Kensa Heat Pumps, said:

We’re delighted to have been awarded funding under EEF to develop the PREDICT dashboard which will benefit our customers and make the transition from gas boilers towards heat pumps more financially favourable.

Linking ground source heat pump operating data with the new dashboard and predictive maintenance package will reduce the costs associated with unexpected maintenance and heat pump ownership, increasing consumer confidence in the technology.

Kensa’s is continually innovating to boost heat pump sales and promote the widespread adoption of the technology. This is necessary if the UK is to increase current levels of heat pump sales to 600,000 a year by 2028 (UKGov Ten Point Plan), helping the country to hit its net zero targets.

The product will benefit many customer stakeholders:

The Boiler Upgrade Scheme is a financial grant backed by the government to support the costs of installing low carbon heating systems, such as heat pumps and qualifying biomass systems for off -gas grid properties. The scheme supports air source heat pumps (ASHP), ground source heat pumps (GSHP) and biomass in qualifying areas.

Factsheet

Version 4.0 | Updated: 06/08/2024

In this article, the Technical Support Team at Kensa Heat Pumps gives their top tips for proactive maintenance on ground source heat pump systems to ensure your customers stay warm and cosy throughout winter.

Before we go into details about heat pump maintenance, if your customers are worried about the price of energy bills, please do share with them this article with Kensa’s heat pump energy saving tips. With the cost of living on the rise and cold weather hitting, people will be thinking about how to keep their energy bills as low as possible. We offer advice on how consumers can lower their energy usage, making their homes more efficient to help to reduce the cost of their energy bills.

One of the unique benefits of ground source heat pumps is their minimal maintenance requirements and long life expectancy. However, as with all heating systems, it is good practice for the heating distribution system, including energy collectors, to be proactively checked and maintained to ensure optimum performance when colder weather is on the horizon.

Temperatures below ground remain relatively constant all year round, so a sudden drop in air temperature during winter will not affect the performance of a ground source heat pump, nor does the impact of exposure to the elements affect the operation, as it would an air source heat pump.

Tom Worth, Kensa Technical Support Manager, says:

Well designed ground source heat pumps require only a minimal amount of maintenance, however, it is important that the whole system is checked.

Tom recommends the following basic checks are made on the heating distribution system:

Tom Worth, Kensa Technical Support Manager, says:

This is where the maintenance of a ground source heat pump system becomes slightly different to that of a standard fossil fuel system, as it is important to ensure that no issues can occur in the collectors that harness the renewable energy from a ground or water source.

Any issues with the energy collection system could mean the heat pump has to work harder and hence becomes less efficient. In the worst case, the source energy could become depleted causing the heat pump to stop operating altogether.

Tom recommends the following quick and easy checks on ground source heat pump energy collectors:

and maintained in line with the manufacturer’s guidelines.

Kensa Heat Pumps has a dedicated Technical Support team that can help, advise and direct any enquiries about Kensa Heat Pump systems. They can be contacted on 0845 680 4328.