Mount Wellington Mine, Truro

Ground Source Review: Mount Wellington Mine, Truro

Kensa Heat Pumps’ manufacturing facility is heated using ground source heat pumps and mine water.

Ground Source Review: Mount Wellington Mine, Truro

History

Mount Wellington Mine in Chacewater, Cornwall, was the last deep tin mine ever to be built in the world. From a three-man operation started by the Wellington brothers in the 1920s, to what was the most advanced tin mine in the world in the 1970s, the site’s chequered past spans over 100 years.

The granite rocks deep beneath Cornwall are enriched in natural radioactive isotopes, including those of uranium. The energy from the decay of these radiogenic elements is dissipated as heat, which is why Cornwall was the epicentre of exploration of the Hot Rocks Project as a source of geothermal energy.

A bright future

After closing its doors on the mining operation in 1991, the site was subsequently acquired by Richard Freeborn of Mount Wellington Mine Ltd in 2007. As opposed to demolishing the existing buildings, he was granted planning consent to create the UKs first privately funded renewable energy business park, spearheaded by the relocation of Kensa Heat Pumps in 2007, which was co-founded by Richard Freeborn and fellow engineer Guy Cashmore in 1999.

Practicing what he preached, Richard chose to use a Kensa ground source heat pump to heat the Kensa manufacturing facility. The factory’s underfloor heating and hot water fed by an 8kW Twin Compact and 13kW EVO in addition to a 3kW Shoebox servicing the production offices. With a wealth of water available in the mine shafts below, a sustainable new lease of purpose was granted to the disused mine workings.

Since acquiring the site investment of over £4m, Mount Wellington Mine has attracted a range of tenants working on renewable technologies including offshore wind and solar thermal, culminating in an official opening in 2012 of the Mount Wellington Mine Renewable Energy Park.

The project at Mount Wellington Mine was the first of three of Cornwall’s four large modern tin mines exploiting the heat found in their mine shafts to heat the converted mine buildings for commercial use. Nearby sister mine Wheal Jane and Geevor at Pendeen have since followed suit.

Further development

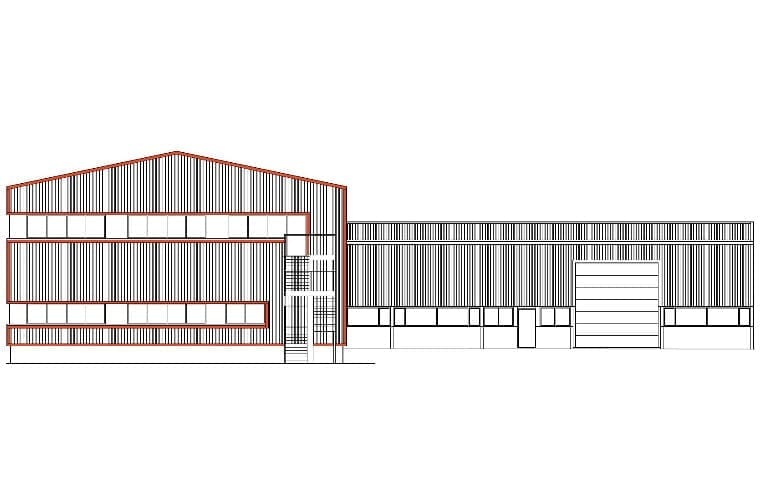

Building on what they started in Cornwall some 20 years ago 2019 sees Kensa begin construction on their new 1000m2 manufacturing and office facility. On completion, the site will be capable of producing 30,000 ground source heat pumps per year keen to meet with the demand for this low carbon, low cost heating technology.

Similarly, the new facility will also harness the heat energy from the flooded mine workings below. The heating and hot water demands fed by two 15kW EVO heat pumps with a further 15kW EVO facilitating cooling of the new offices.

Inclusive of the new factory, Kensa’s carbon savings on the Mount Wellington site are now set to be somewhere in the region of 33.5 tonnes per year with further carbon savings from increased heat pump sales equivalent to taking 60,000 cars off the road.

Quotes

Geevor’s Chairman Bill Lakin explained the initial idea:

Any miner will tell you just how hot it is down a Cornish tin mine. Kensa has pioneered a simple and robust way to harness this heat energy using a ground source heat pump. A large quantity of special plastic pipe – called a geothermal array – is lowered into the mineshaft, and a mixture of water and antifreeze is pumped down from the heat pump. What returns to the surface is warm water at between 12 and 20 deg C, which the heat pump then upgrades to a more useable 35 to 40 deg C for use in underfloor heating.

Mark Giddings, Manager at Wheal Jane, comments on using the extensive local mining workings as a heat source:

So often, old mines are seen as a problem whereas in fact they hold the key to reducing our dependence on fossil fuels – there is a source of renewable energy right under our feet!

Richard Freeborn, the owner of Mount Wellington Mine and founder of Kensa Heat Pumps confirms:

This is the first building in Europe to use heat from the decay of radioactive isotopes, and it is working very well indeed. The heat energy from the mine is 100% renewable. The geothermal arrays have no servicing or maintenance, and a predicated life of over 100 years. The heat pumps are running at an incredible efficiency, thanks both to the warmth of the mine, and the very high standards of insulation in our manufacturing building.

In a speech given by Sir Tim Smit during the mine’s official reopening, Mr Smit remarked:

I truly admire Richard for what he has achieved here – his vision has been realised and it is quite remarkable. What has forged Britain has been technical skills, manufacturing, and design ingenuity. Britain at the moment is going through a green renaissance the likes of which there has never been on planet earth, and it is all being led by British science.

Pete Goss MBE commented:

I love what Richard and his team have achieved so far at Mount Wellington – it’s just great to see so much activity in the Cornish renewable energy industry. I wish them fair winds as they build national businesses from their Cornish base.

Ground Source Review: Mount Wellington Mine, Truro - 1975 aerial view

Ground Source Review: Mount Wellington Mine, Truro

Ground Source Review: Mount Wellington Mine, Truro - manifold

Water for the ground source heat pump in mount wellington mine shaft

Installing ground source heat pump arrays in the mine

Ground Source Review: Mount Wellington Mine, Truro - survey

Original Office building before purchase

Original Factory Building before purchase

New Kensa factory design schematic

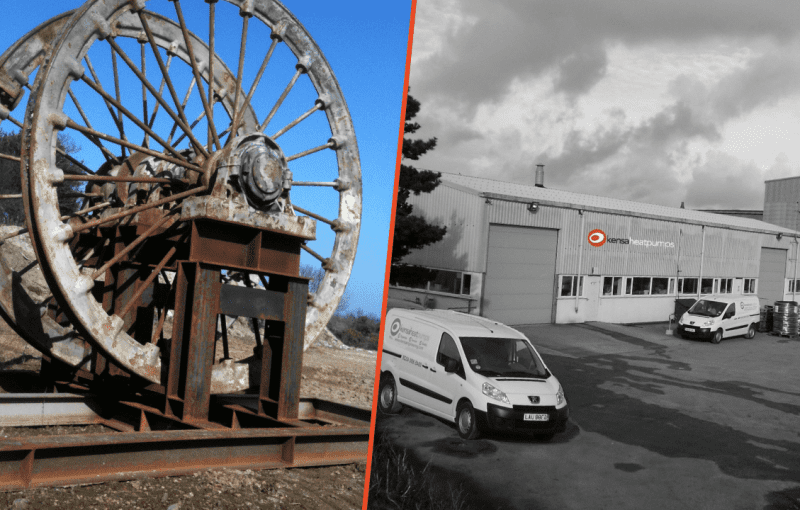

Original Mining Wheel marks the entrance to the Mount Wellington Mine Renewable Energy Park.

Sir Tim Smit with Richard Freeborn at the Mount Wellington Mine Renewable Energy Park opening

Kensa's original manufacturing facility complete

Kensa's Factory in it's infancy

New Evo heat pump on the factory floor

Kensa's Existing Office Facilities

Kensa staff unveiling of the Evo

New Factory Steel Construction

New Factory drone picture

New Kensa factory design schematic

New Factory Windows In