Ground source heat pumps can extract heat from three types of renewable sources: soil, rock and water. They do this by using buried collectors called ground arrays.

Ground source heat pumps can extract heat from three types of renewable sources: soil, rock and water. They do this by using buried collectors called ground arrays.

Surface soil is usually an ideal source for properties in rural areas, or any building with a fair amount of surrounding land (40m x 12m). This allows room for long and shallow trenches.

To extract the heat from surface soil, a network of ground collectors, consisting of a series of pipes, is buried in the ground in trenches to a depth of 1 – 2m. Typically consisting of coiled pipe, collectors of this nature are referred to as ‘slinkies’.

See more about slinkies & straight pipes

Rock is a perfect conductor for heat energy, particularly for properties with minimal land such as tower blocks, flats, businesses or homes with limited garden space.

Boreholes are the collectors used to extract heat energy from rock for ground source heat pumps. To extract heat from the rock, a U-tube pipe is installed into a drilled hole measuring 60-200m deep by 150mm wide. Boreholes are a very discreet and compact solution when saving space and minimal ground disruption is a priority.

See more about boreholes

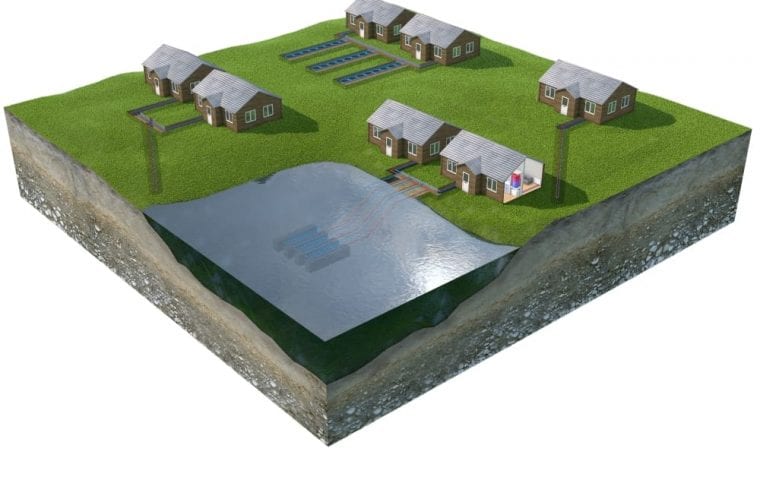

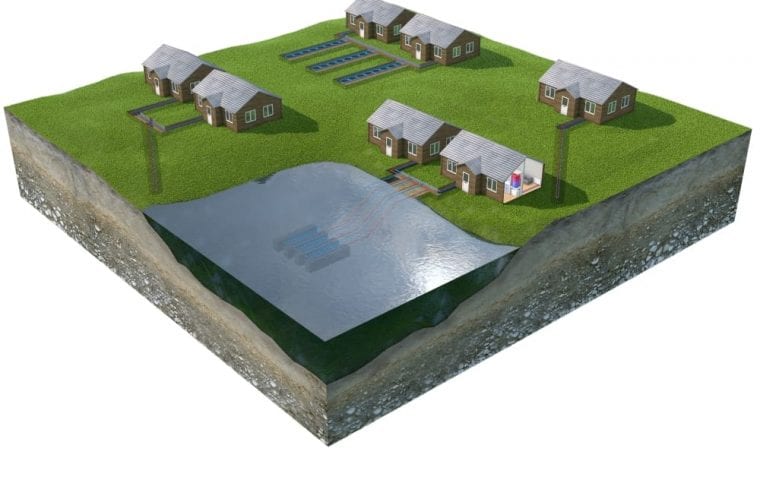

Water is the most efficient source of heat transfer and is suitable for any property within 100m. Water sources include lakes, ponds, rivers, the sea, and even aquifers – all of which are successfully used by Kensa to provide heating and hot water to residents on the shoreline (or in boats)!

Pond mats are typically used to extract heat from water sources, but methods such as boreholes and submerged open-loop pipework are also used to great success.

See more about water source

I knew that ground source was a great technology for extracting the natural heat that’s available from the environment to provide a completely green heating system. The good thing about the pipes being in the lake is that water has great conductivity meaning we are able to extract heat sustainably throughout the winter to keep the house perfectly warm.Mr Clarke, homeowner

Renewable heat taken from the ground or water is predominantly stored solar energy. This is naturally replenished through direct solar energy, and indirectly through the rain. Stored solar energy is different from geothermal heat, which is absorbed from the earth’s core by digging much deeper into the ground.

The heat source you use can be determined by how much space you have around the building. This is because the area needed for ground source heat pumps will either require horizontal groundwork for soil or water, or vertical groundwork for rock.

Submit your plans for adviceThe space you need for a ground source heat pump varies depending on the ground collector used. A typical property using slinky pipes in trenches will require an area of land measuring around 40m x 12m. Boreholes can range from 60-200m deep and 150mm wide. And water must be within 100m to be used as a heat source.

The two most commonly used in the UK are slinky pipes and boreholes. However, pond mats in water should be the preferred option if there is a pond, lake or any sort of water source nearby.

An open loop system is a less commonly used collector. It uses the sea or a large body of water as the source, absorbing, compressing and delivering heat to a building, and then circulating the water back into the source or a discharge area.

A mixture of glycol and water is pumped around the pipework buried in the ground. The collectors absorb some of the energy in the ground and transfer this energy back to the heat pump. The heat pump then compresses and delivers heat into the property at its desired temperature.

Heat collectors are sized to meet the heat needs of the building, not the heat pump. All collectors have broadly the same performance, and a building’s thermal efficiency affects heat pump performance more than the type of collector.

more on how a heat pump system works

As the most commonly used collectors in the UK, it’s likely that you’ll be choosing between a ground source heat pump borehole or trench. Here are the key differences between the two:

Slinky trenches are usually cheaper and easier to install. They don’t need a specialist drilling contractor, and the installation work can be undertaken by a digger that is already onsite doing other work.

However, slinky pipes must have sufficient land area to collect and deliver the energy requirements of the building. Adding more loops into a limited area of land doesn’t increase the amount of energy available – the limiting factor is the land itself, not the pipes in it.

Boreholes on the other hand are typically a more expensive option, especially on smaller jobs – and getting physical access for the drilling rig may be a challenge on space-restricted sites.

Having said that, boreholes can usually be installed in any type of ground. The smallest of gardens meet the heat load of the property, as the depth of boreholes vary to suit the heat requirement. Boreholes can be sited under car parks and even under the buildings themselves, as unlike horizontal arrays, they are far less affected by what’s directly above them.

Water source heat pumps collect energy from places such as streams, lakes or ponds, whereas ground source heat pumps absorb heat from the ground below us.

However, in terms of the physical system itself, a water source and ground source heat pump is the same. Kensa’s ground source heat pumps can collect energy from both ground and water – such as soil, rock and even the sea.

There are many things to consider when it comes to choosing a heat source and collector. Remember that Kensa can help you with anything from finding an installer, to design or commissioning support. If you’re an installer yourself, you can even use our MCS Umbrella Service.

Factors to consider when choosing a heat source include:

If you are within reasonable reach (100m) of a water source such as lake, stream, or the sea, this should be your first option for a heat source. Water has exceptional thermal conductivity and cheaper installation costs.

Borehole drilling is the most expensive of the ground array options, but it’s the quickest and least invasive option.

The ground conditions and conductivity of the underlying geology will influence the cost of any ground array.

An accurate heat loss calculation for the building is absolutely essential when designing any ground array for a ground source heat pump system. If you need help with this, Kensa conducts calculations as part of our MCS service.

The water temperature at which the heating distribution system runs will change the efficiency (CoP) of the heat pump system. So a system using underfloor heating will normally need a slightly larger ground array than one using radiators in an identical building.

One of the ironies of using an ultra-efficient heat pump like the Kensa Evo model is that the ground array size needs to increase slightly. If less energy for a given heat output is coming from electricity, then more has to come from the ground array.

As a general rule, you need a garden area of at least 40m x 12m to install horizontal heat collectors in the soil.

Surprisingly often, calculations for a horizontal array will show that the available garden area isn’t quite big enough to meet the heat load. The usual solution for this situation is to go down the borehole route, but this could add several thousand pounds to the overall installation cost.

It could be worth spending this money on insulation to reduce the heat load and energy bills. By reducing the heat load, the available garden area can become a viable heat source. It may also be possible to specify a smaller heat pump, which will further offset the insulation costs.

Ground arrays can be shared between multiple properties in a similar fashion to district heating. Each property will have its own heat pump, and the system won’t need any metering or billing arrangements – this is known as Networked Heat Pumps.

The boreholes or slinkies can be sited where practical rather than individually in gardens. As the system grows in size, a degree of diversification can be applied – so the total area for the ground array can be reduced compared to individual systems.

Less commonly, other sources of free energy can be found in existing water wells, old mines, natural springs, river water and even seawater. While these projects aren’t so mainstream, the best ones can make highly efficient and low-cost energy sources.

Submit your plans for adviceNetworked Heat Pumps are Kensa’s award-winning and pioneering approach to district and communal heat networks – without the drawbacks of traditional district schemes. The design connects ground arrays to individual heat pumps in multiple dwellings.

Traditionally, rock is utilised as the heat source via borehole collectors for use in Shared Ground Loop Arrays, however, water sources could provide significant groundwork savings and deliver even more efficient results.

See more on Networked Heat Pumps

Learn about the different types of ground arrays compatible with Kensa Ground Source Heat Pumps, and gain expert advice on their specification and installation. In this video you will discover how to select the most suitable ground array for your project, and follow a step by step guide to sizing and installation, supported by ground…

This Kensa Contracting commissioned motion graphic depicts the key stages for the installation of Kensa Shoebox ground source heat pumps into individual flats in tower blocks, connected to shared ground loop array boreholes. For more information on this application click here. *Please note: the Non-Domestic RHI funding stream mentioned in this video has now expired….

Kensa Heat Pumps has released a new video showing how best to unroll coiled slinky pipe for a ground source heat pump installation.

Mr Clarke replaced his gas boiler with a Kensa 24kW Single Phase Twin Compressor* to harness heat energy from a nearby lake to provide space heating and domestic hot water (DHW) to his Grade 2 listed farmhouse. Key facts: 24kW Single Phase Twin Compressor Replaced mains gas boiler Large, Grade 2 listed farmhouse Highly efficient…

Our Technical Director Guy Cashmore has put together some helpful hints about ensuring you get the design and installation of the ground array right.