Boasting three-phase, the series’ modular units provide flexibility to match and balance the heating demands of commercial buildings.

To efficiently meet fluctuating demands, multiple units can be connected together in a cascaded system.

Simple integration with new or existing radiators, fan coils or underfloor heating. Multiple units can also be controlled via a Building Management System (BMS).

Depending on your project type, there is a range of funding options that we can advise you on. Visit this page to explore different types of funding.

The series is comprised of modular three-phase models that deliver tailored outputs, flexibility and compatibility in large or commercial buildings.

The Kensa Q is the perfect candidate for a cascaded system. Efficiently fulfilling fluctuating demands, multiple units can work together to deliver large space heating and hot water demands at the same time.

With multiple heat pumps, heating and hot water can be provided to different parts of a building simultaneously through a Building Management System (BMS).

Designed for ease, the Kensa Q is compatible with a building’s heating distribution system, such as fan coils, underfloor and air handling units.

James Stockan - Orkney council chairman

The Kensa Q offers low running costs, lack of annual servicing requirements and minimal maintenance over its 20-year design life.

With up to 5 years guarantee, every Kensa heat pump comes with technical support for life. This includes anything from advice for installers to post-installation guidance for end users (terms and conditions apply).

Charles - Garden centre owner

Whatever your project, Kensa can help. Our installation services are perfect for projects of all shapes and sizes.

Need an installer?

Submit your plans and we’ll recommend a local Kensa-approved installer.

Need support?

Our design and technical support will guide installers through the whole process.

Planning a large-scale project?

If your development has multiple buildings or requires specialist support, our award-winning heat pump contractors at Kensa Contracting can help.

Jamie Burnham - Installer

See more reviewsThe Kensa Q comes with Kensa’s technical support for the system’s lifetime. Get guidance from our technical team on anything from commissioning to post-installation.

See how we support youIn this project, heat pumps use the sea as a heat source to deliver heating and hot water to Orkney council offices.

See Orkney council's case study

Jamie Burnham - Installer

See the case studyNew purpose-built outdoor education centre

2 x 30KW commercial untis providing heating and hot water

10 x pond mats under pontoon in the harbour

£1600 per year running cost

Budget £32k

James Stockan - Council chairman

See the case studyOrkney Council offices

2 x 40kW commercial ground source heat pumps providing heat and hot water

2 x pond mats submerged beneath the pier in Stromness harbour

£1000 savings compared to oil

Six tonnes of CO² per year

Charles - Garden centre owner

See the case studyNew-build extension providing 30,000 sq ft of retail space

Cascaded commercial system

2x 45kW commercial ground source heat pump providing space heating

1x 25kW High temperature commercial providing hot water

24x 50m slinkies located under nearby field

Main building upgraded to underfloor heating

System contains 7250 litres of water and 1450 litres of antifreeze

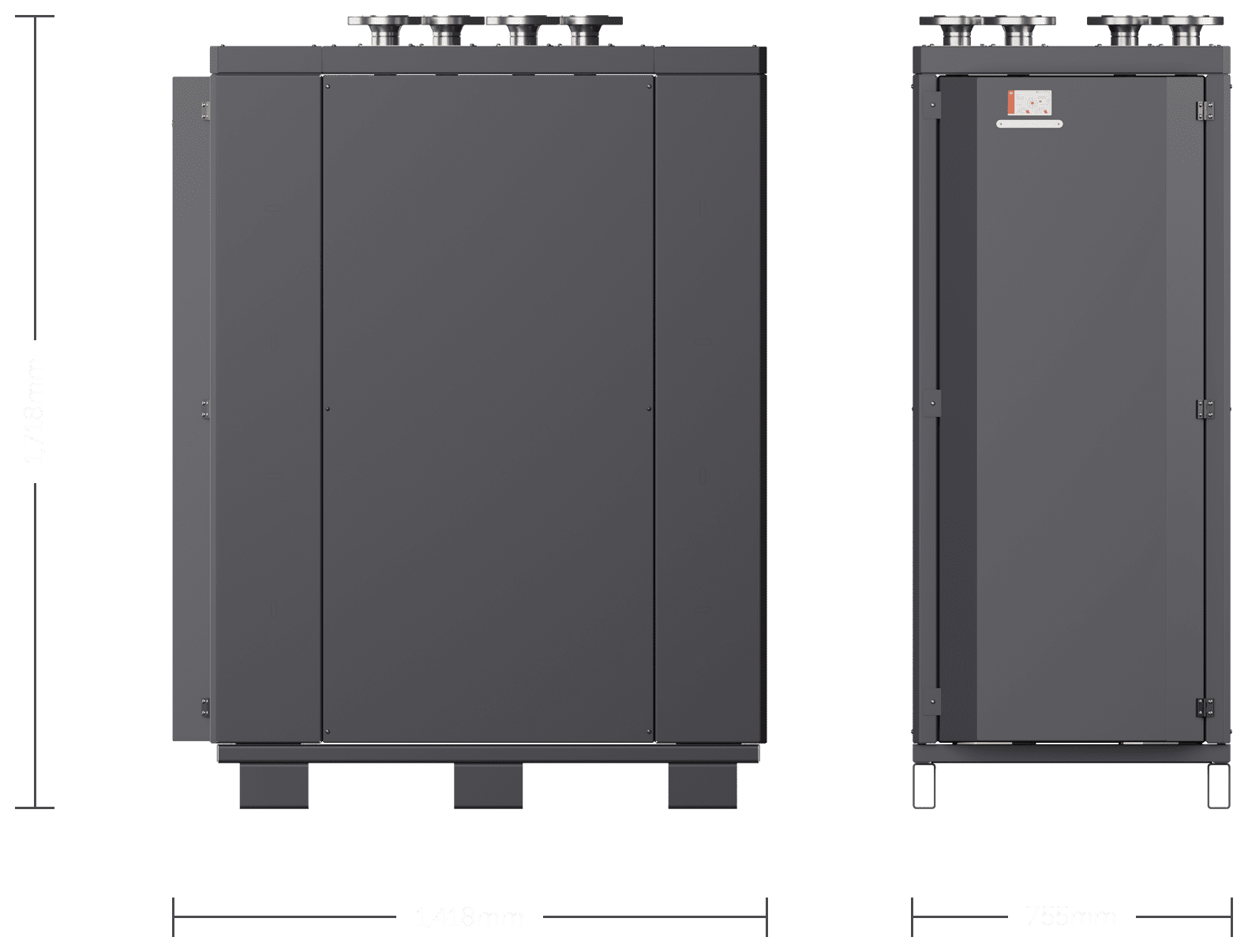

1718mm high

755mm wide

1418mm deep

| Three Phase | |

| Nominal thermal kW rating | 83 |

| MCS approved | Not required as outside of scope |

| Product Code | Q80-MAK |

| Performance data—rated heating output at B0/W35 BS EN14511 | |

| Power consumption kW | 20.5 |

| Coefficient of performance* | 3.94 |

| Immersion heater output | Kensa heat pumps do not feature back-up electric immersion heaters** |

| Brine (primary) based on 0oC in, -4oC out | |

| Design flow rate l/min | 359 |

| Pressure drop kPa at design flow rate | 46.3 |

| Max inlet temperature oC | 15 |

| Min temperature oC (Outlet) | -5 (at standard settings) |

| Heating water (secondary) based on 30oC in, 35oC out | |

| Design flow rate l/min | 240 |

| Pressure drop kPa at design flow rate | 27.6 |

| Max flow temperature oC*** | 64 |

| Electrical Values @B0/W35 | |

| Rated Voltage | 380-420V/ 50 Hz |

| Power supply rating amps | 65 |

| Rated current (max) amps | 64 |

| Typical running current @ B0/ W35 amps | 38 |

| Starting current amps**** | 118 |

| Power Factor @ 0/35C | 0.74 |

| Performance data—rated heating output at B0/W55 BS EN14511 | |

| Power consumption kW | 27.5 |

| Coefficient of performance* | 2.75 |

| Heating water (secondary) based on 47oC in, 55oC out | |

| Design flow rate l/min | 138 |

| Pressure drop kPa at design flow rate | 10.4 |

| Electrical Values @B0/W55 | |

| Rated Voltage | 380-420V/ 50 Hz |

| Power supply rating amps | 65 |

| Rated current (max) amps | 64 |

| Typical running current @ B0/ W55amps | 46 |

| Starting current amps**** | 118 |

| Power Factor ‘@0/55C | 0.82 |

| Refrigerant circuit | |

| Process medium | R407C |

| Fill volume kg | 6.8 |

| Compressor type | Twin Scroll |

| Dimensions (nominal) | |

| Height (mm) | 1718 |

| Width (mm) | 755 |

| Depth (mm) | 1418 |

| Dry weight kg | 665 |

| Operating pressure | |

| Brine circuit min (primary) bar g | Installer configurable |

| Heating water circuit min (secondary) bar g | Installer configurable |

| Low pressure reset bar g | Installer configurable |

| Connection sizes | |

| Primary IN and OUT PN10/16 | DN50 |

| Heating flow and return PN10/16 | DN50 |

| Performance (based on Average Climate) @35oC | |

| ErP rating | A++ |

| SCOP | 4.14 |

| Seasonal space heating energy efficiency | 158% |

| Performance (based on Average Climate) @55oC | |

| ErP rating | A+ |

| SCOP | 3.48 |

| Seasonal space heating energy efficiency | 131% |

| Sound Power Level | |

| dB (A) | 72.3 |

* The COP figure quoted excludes the water pump electrical input and is calculated according to EN14511.

** In-built immersion heaters will increase running costs and CO2 emissions as they use direct electricity, because of this Kensa heat pumps do not include them.

*** By increasing the flow temperature from the heat pump the efficiency of the unit will drop and the COP decreases.

**** The starting currents are per phase. For full details on how the starting currents are calculated please contact Kensa.

Note: Design flowrates and pressure drops are based on a ground temperature of 0 and –3oC and a load temperature of 30oC and 35oC or 47° and 55°C.